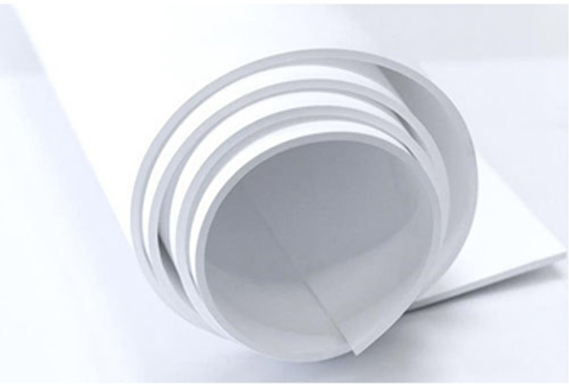

Teflon sheet is used commonly when using a heat press to transfer designs onto fabric. It prevents ink from staining and transfers from sticking to the heat plate. Teflon eliminates scorching on products.

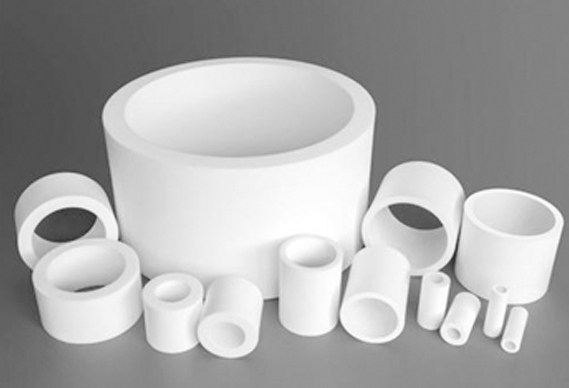

PTFE has high temperature and chemical resistance, it is usually used for valve applications. From simple steam / hot water valves to high temperature, fluid handling industries caustic chemical valves. This material is semi-rigid to rigid plastic and can be easily machined — one of the easiest to use plastic.

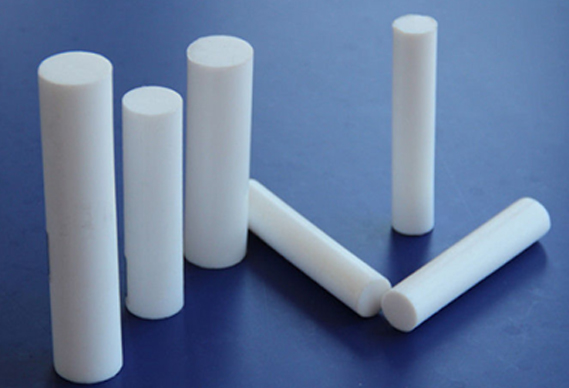

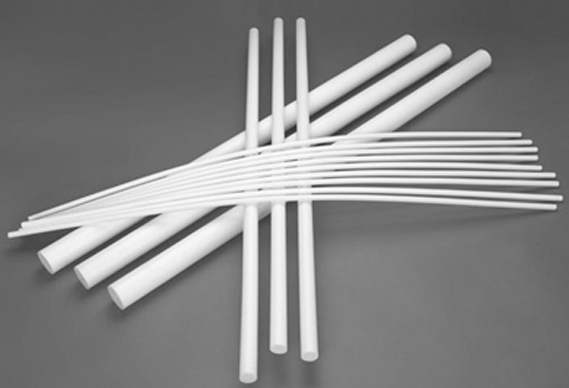

PTFE is excellent for low friction bearings, bushes, rollers and pulleys. PTFE is also almost exclusively used in cryogenic components due to its ultra low operating temperatures. PTFE Rod is regularly used for seals.

PTFE films are used to provide a high temperature, chemical resistant material in a number of applications. Our PTFE films are either skived or cast. Skived film products include premium skived, flex barrier and UHMWPE.

PTFE extruded tubing is suitable for applications that require protection from chemicals and high temperatures. This tubing is highly flexible, making it ideal for use in various applications including electronics, aerospace and medical.

PTFE Adhesive Glass Cloth (with protect yellow paper) is well known as its smooth surface, non stick, chemical resistance and high temperature resistance and insulation prosperities. It is widely used in packaging, heat molding, laminating, sealing and electrical industries etc。

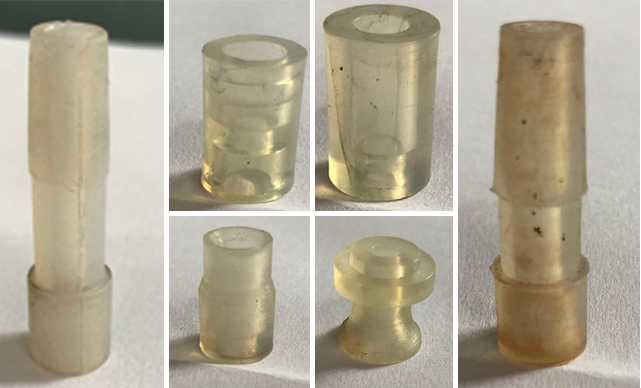

PTFE MOULDED BUSHES These are the bushes which are widely used in many industries because of their properties that make them chemically resistant, light weight and non-toxic.

Thread seal tape (also known as PTFE tape, Teflon tape, or plumber's tape) is a polytetrafluoroethylene (PTFE) film tape commonly used in plumbing for sealing pipe threads. The tape is sold cut to specific widths and wound on a spool, making it easy to wind around pipe threads.

Applications include PTFE balls used in chemical handling pumps, check valves, ball bearings for light loads, volume displacement balls for chemical baths and many other uses.

Teflon or PTFE washers are flat discs with a centrally located hole. They have superior antifriction properties, as well as excellent chemical and corrosion resistance. These washers are ideal for low-temperature applications. Washers can do way more than secure bolts, nuts, screws, and rivets.

Carbon filled PTFE has excellent compressive strength, wear and chemical resistance. It provides good thermal conductivity and low permeability. An ideal material for dynamic sealing applications. The addition of Carbon Fibre to PTFE increases the compressive strength and wear resistance.

used to produce ptfe moulded and extruded rod and sheet and ptfe components

(Polytetrafluoroethylene) as a base material. It provides strength, elongation, chemical resistance, weather resistance, electric insulation, heat resistance, and can be used under various environmental conditions.

Good thermal, conductivity, Low wear and high extrusion resistance, Wide fluid application range, Resistance against cold flow. Application: Mobile Hydraulics, Injection molding machines, Machine tools, Material Handling Equipments, Control and regulating apparatus.

Better dimensional stability and lowers creep, cold flow and wear. The addition of Bronze to PTFE gives better dimensional stability and lowers creep, cold flow and wear. It increases hardness and compressive strength whilst also increasing thermal and electrical conductivity.

PTFE envelopes gaskets are a highly useful sealant for liquid and gas inside the pipelines. They help in preventing the leakage of the acids and chemicals passing through the flange joints, valves, etc. Food processing companies need to be very careful about contamination to avoid any mishaps.

It has excellent thermal and electrical insulation properties and a low coefficient of friction. PTFE is very dense and cannot be processed by melting. PTFE must be compressed and sintered to form useful shapes. PTFE is easily machined on all standard equipment, including the most advanced CNC machining equipment.

General Industrial PTFE Components. Chemical Handling such as Valve Bodies, Seats & Seals, Balls and Pump Parts. Semiconductor Processing Industry including custom Labware and Tools. PTFE Containers, Funnels and Molds for Pharmaceutical & Biotech research.

Expanded PTFE is a sealing agent that is made of 100-percent pure PTFE. The expansion process produces a microporous fibrous structure which gives the product its unique mechanical properties. The material is specially targeted for sealing flange joints in pipelines and hydraulic and pneumatic systems.

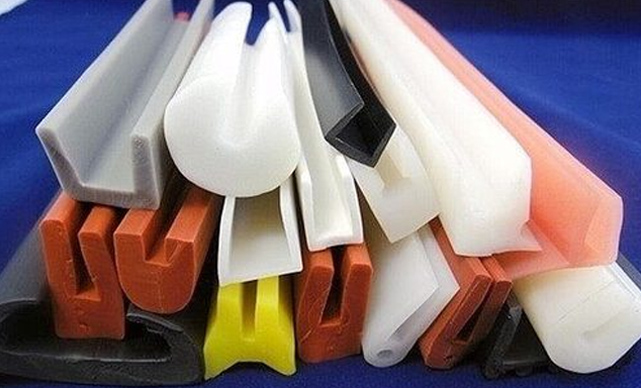

We are engaged in offering an array of Silicone Autoclavable Gasket (Extruded Door Gasket). We offer them in more than 1000 different shapes and designs. The soft Silicon Sponge Gasket (Hardness range from Shore A15 to 30) to solid silicon Gasket (Hardness range from Shore A35 to 85). We use premium grade Food-Pharma Grade Silicon Rubber in the production. The use of these raw material helps in withstanding high temperature. We offer these gaskets in square cross sections like 20 mm x 20 mm, 25 mm x 25 mm x 25 mm with central hole of 10 mm diameter. To make them look more elegant these gaskets are offered in red, white, orange and other as per the specific requirement of the clients. These are widely appreciated for their dimensional preciseness, sturdiness, flexibility and longer functional life.

We are the manufacturers of Silicone Endless Gaskets. Silicon Endless Gaskets are manufactured by step molding process. These available in various sizes and thickness as per the need of the customer.

We are one of the preeminent manufacturers and exporters of qualitative Silicone Sponge Gaskets. These are produced and offered to customers in round square and rectangular cross section with multiple color options. Our silicone sponge gaskets conform to the standards PDA 21 CER 177.2600. These gaskets are used in industrial segments like tractors & farm machinery, components/assemblies manufacturers’ hydraulic machinery and flanges and fittings.

We are the leading manufacturer and exporter of qualitative Silicone Tri Clamp Gaskets. These are offered with collar for a better grip and are available without this option also. These are widely use in the industrial segments inclusive of hydraulic machinery, commercial vehicles, components and assemblies manufacturers and tractors & farm machinery. For a better and excellent chemical compatibility. We use qualitative standard silicone rubber. These are produced in various shapes and sizes and offered in customized shapes. The gasket inflates, seals the bowl and ensures proper sealing. Details:- Material: Transparent silicone of highest standard (FDA21CFR 177.2600), food pharma grade white neoprene rubber Inflated by 10 mm to 12 mm when 2 to 4 kg. Capacity ranging from 5 kg to 500 kg Features: Flexible High tolerance Abrasion resistance Specifications: Gasket Sealing Material Dimension PC-Top Bowl Sealing Neoprene Rubber 40 mm x 22 mm PC-Bottom Sealing Neoprene Rubber 40 mm x 22 mm Fitter Press Bag Sealing Gasket Neoprene Rubber 50 mm x 20 mm

AB Polytech Engineering LLP is pioneer in Polyster reinforced Silicone Transparent Braided Tubes for Food, Pharma, Chemical, Medical, Heavy Engineering, Thermal Power Stations, and PSUs. These Braided Hoses are made from 100% pure Silicone Rubber by using fully Automatic state-of-the art machineries and technologies. We have already catering these products to all the major Pharmaceutical Companies in India . Our products are also exported for overseas customers. AB Polytech Engineering LLP is pioneer in Polyster reinforced Silicone Transparent Braided Hoses for Food, Pharma, Chemical, Medical, Heavy Engineering, Thermal Power Stations, and PSUs. These Braided Hoses are made from 100% pure Silicone Rubber by using fully Automatic state-of-the art machineries and technologies. We have already catering these products to all the major Pharmaceutical Companies in India . Our products are also exported for overseas customers.

Ready avail in various sizes and polymers

We are engaged in providing a qualitative range of Silicon Rubber Cords.These Silicon Rubber Cords are widely used at places of high temperature. These have been manufactured using standard quality rubber and allied materials and have outstanding resistance properties. Our range is available in different varieties, sizes and dimensions as per the requirement of the client.

We produce a wide range of Silicone O Rings from ID 1.0 mm to 700 mm from its 7000 single piece moulds. We have also profitably drafted viton O ring of ID upto 3000 mm. These O rings are manufactured on a hydraulic press with tightly controlled temperature and time, and ensures accurate dimension, excellent finish, invisible flash line, properly post cured and absolutely defect free.

AB Polytech Engineering LLP offers it's wide range of O-rings from 2.0 mm ID to 600 mm ID from its 5000 single piece moulds. O-Rings are manufactured on a hydraulic press with tightly controlled temperature, Pressure and time which ensures accurate dimensions, glossy finish, invisible flash line, properly post cured and absolutely defect free. hese O-rings are also manufactured as per the dimensional tolerance specified by the customers and available from NBR, Neoprene,EPDM,Viton and Silicone Rubber or in any other rubber as per customers specification. We also manufacture O-Rings upto 3000 mm ID or in any sizes through step moulding process which gives joint less O-Rings of dimensionally accurate and excellent workmanship and finish.

These sponge Gaskets and strips are manufactured from technologically advanced fully automatic microwave curing system which ensures uniformity, and totally controlled dimensions and glossy finish. Silicone Strips and Sponge gaskets are also manufactured in STEP MOULDING PROCESS as per the customers requirements where the accuracy of dimensions are prime important and the edges are required very sharp.

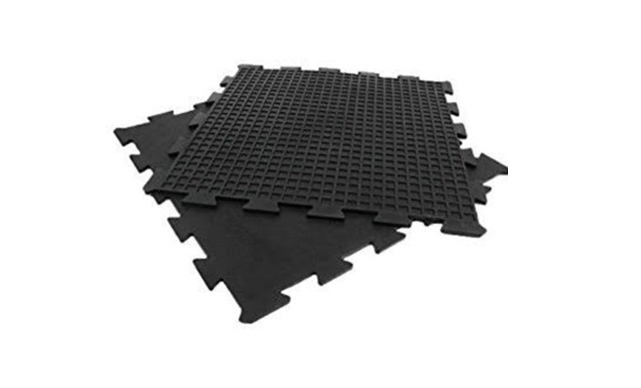

Ready available in various polymers and sizes

Ready available in various polymers and sizes

USE:- The application of silicone tubing can depend on the size of the tubes. Due to its thin walls and flexibility, they are used most commonly as electrical sleeving. Used to carry liquids and powders thereby making it popular with the pharmaceutical and food industries.